Spare tires have saved many of us from becoming stranded along highways or remote roads, and are a standard inclusion on most vehicles.

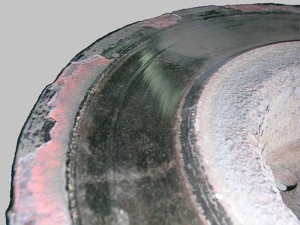

In older vehicles, the spare tire was often the same tire being used on the rest of the vehicle. However, with the infrequent use of a spare tire, manufacturers began moving towards space-saving “donut” style spares, which are temporary tires much smaller and skinnier than their full-size counterparts.

These tires are meant only to be temporary of course, but how temporary? How long can you drive on your spare tire?

Donut Spare

Space-saver spares, otherwise known as donut spares, are the size of spare tires used in most modern vehicles. These tires are smaller than the normal tire size and are only to be used for driving straight to the tire shop after encountering a flat.

This type of spare is also inflated to a much higher tire pressure than a traditional tire. Most small/compact vehicle tires should be inflated to around 35 PSI, while donut spares often need about 60 PSI of pressure.

These tires should be driven no longer than 50 miles, or however long it takes to get to the nearest tire shop. The difference in size and tread will cause less traction and durability than a normal tire, and the driving mechanics of the vehicle will be considerably thrown off. With the spare tire also having a smaller diameter, driving an excessive amount on your spare can cause damage to your transmission or differential.

Full-Size Spare

On older and larger modern vehicles, it’s common to see the full-size spare instead of the donut-style spares, which have become more popular recently in the majority of vehicles.

However, full-size spares are much better in terms of longevity, as they are the same size tire that came on the car originally. This means that you can drive on a full-size spare considerably longer than a donut.

This doesn’t mean you should settle for having a spare tire installed though, you should still have your spare swapped out for a new tire as soon as you can. Differences in tread, manufacturer, and width can make driving with it difficult. It’ll just drive more like a regular tire in the meantime.

How do I Drive Safely on a Spare?

If you run into a situation where you need to use a spare, there are some steps you can take to make sure you’re staying as safe as possible.

Don’t Drive Like You Normally Would

While it may be tempting to step on the gas and try to speed up your trip after stopping to change a flat, you should be doing the exact opposite. Since spares (especially donuts) don’t drive the same as a normal tire, you should limit your speed to around 50 MPH and give yourself more than enough time and space to safely slow down, change lanes, and take corners.

Along with the differences in tire size and tread, using a spare can disrupt your traction control and stability control system. Without these safety mechanisms, it’s imperative to drive with caution in mind to avoid dangerous situations.

Ensure Spare is in Proper Condition

Spares should be checked regularly for adequate tire pressure and check for any holes or leaks. The last thing you want to happen after getting a flat tire is for the spare to be flat as well.

Before any long road trip, give it a quick look to make sure you’re prepared, especially if driving through rural stretches of highway with few tire shops along the way.

Be Extra Cautious in Bad Weather

Since the tread on spare tires is not up to the same spec as the tread on the rest of your vehicle’s tires, you should be especially careful in rain, snow, fog, or any other inclement weather conditions. Make sure to provide yourself extra time and distance to brake and turn, and drive defensively to avoid needing to drive evasively (even more than you would normally with a spare).

Run-Flat Tires

A few vehicles (namely BMWs and other luxury vehicles) may come from the factory equipped with run-flat tires. These tires are designed to temporarily drive after being punctured and follow similar driving guidelines to spare tires. Limit yourself to 50 MPH and around 50 miles of driving on the way to have it replaced.

These tires are often labeled with ROF (Run on Flat), EMT (Extended Mobility Technology), or ZP/ZPS (Zero Pressure). These labels vary by manufacturer, but all are used to designate run-flat tires.

Tire Replacement at Matson Point S

If you’re in the Salt Lake Valley and need a tire replaced, visit the friendly and experienced team at Matson Point S. We’ll help you choose, mount, balance, and install the right tire for your vehicle! Call or schedule online.