In 2018, Utah removed safety inspections as a requirement for registration for most cars and trucks. Save a few exceptions, you can register any vehicle in Utah without a technician or mechanic signing off on it.

However, all vehicles are still required to have an emissions check performed. Emissions checks verify that a vehicle is not releasing excessive noxious gasses into the air while operating. The type of check and frequency varies depending on the vehicle type and year it was manufactured.

How often do I need to get an emissions check?

Only five of Utah’s 29 counties require emissions checks. They have a slightly different rule regarding the frequency of emissions checks.

Salt Lake County Emissions Rules

If your vehicle is less than six years old, you are required to get an emissions inspection every two years. A car with an odd number model year must get checked on all odd number years to meet the biennial interval requirement (cars with an even model year are checked on even-numbered years). Vehicles older than 6 years require yearly emissions inspections in Salt Lake County.

Exemptions

- Any model year 1976 and older

- Diesel vehicles made in 1997 or earlier with a GVWR (gross vehicle weight rating) under 14000 lbs

- Motorcycles

- EV’s (electric vehicles)

- Agriculture and farm vehicles

- Vintage cars

- Off-highway vehicles

- Construction/maintenance vehicles

- Military vehicles

Utah County Emissions Rules

Gas vehicles registered in Utah County follow similar rules to those in Salt Lake County. Cars and trucks 6 model years old or newer require an inspection every two years, and cars older than six model years but newer than 1967 require yearly inspection. Anything older than the model year 1967 requires no inspection. Diesel vehicles with modal years from 1998 to 2016 require yearly inspections.

Exemptions

- Any model year 1967 and older

- Diesel vehicles made in 1997 or earlier with a GVWR (gross vehicle weight rating) under 14000 lbs

- Motorcycles

- EV’s (electric vehicles)

- Agriculture and farm vehicles

- Vintage cars

- Off-highway vehicles

- Construction/maintenance vehicles

- Military vehicles

- Diesel vehicles from 2017 or newer

Davis County

Davis County follows the same rules as Utah and Salt Lake Counties but requires light, medium, and heavy-duty diesel engines to follow the same inspection intervals.

Exemptions

- Any model year 1967 and older

- Diesel vehicles made in 1997 or earlier with a GVWR (gross vehicle weight rating) under 14000 lbs

- Motorcycles

- EV’s (electric vehicles)

- Agriculture and farm vehicles

- Vintage cars

- Off-highway vehicles

- Construction/maintenance vehicles

- Military vehicles

- Any heavy-duty diesel meeting the following criteria:

- IRP registration

- GVWR greater than 26.000 lbs

Weber County Emissions Rules

Vehicles in Weber County follow the same emissions rules as those registered in Salt Lake County. Cars and trucks less than six years old need inspections every two years, and cars older than six years require yearly emissions checks.

Exemptions

- Any model year 1967 and older

- Diesel vehicles made in 1997 or earlier with a GVWR (gross vehicle weight rating) under 14000 lbs

- Motorcycles

- EV’s (electric vehicles)

- Agriculture and farm vehicles

- Vintage cars

- Off-highway vehicles

- Construction/maintenance vehicles

- Military vehicles

Cache County

Cache County has unique emissions policies that set it apart from the other counties in Utah. Vehicles six years old or newer are not required to undergo any emissions inspection. Any vehicles older than six years require biennial emissions checks. The cutoff for age in Cache County is the model year 1969. Any vehicle produced in 1968 or before is exempt from emissions inspections.

Exemptions:

- Any model year 1968 and older

- Diesel vehicles made in 1997 or earlier with a GVWR (gross vehicle weight rating) under 14000 lbs

- Motorcycles

- EV’s (electric vehicles)

- Agriculture and farm vehicles

- Vintage cars

- Off-highway vehicles

- Construction/maintenance vehicles

- Military vehicles

For more information on Utah’s emission rules, check out the Utah DMV website.

What does an emissions inspection look like?

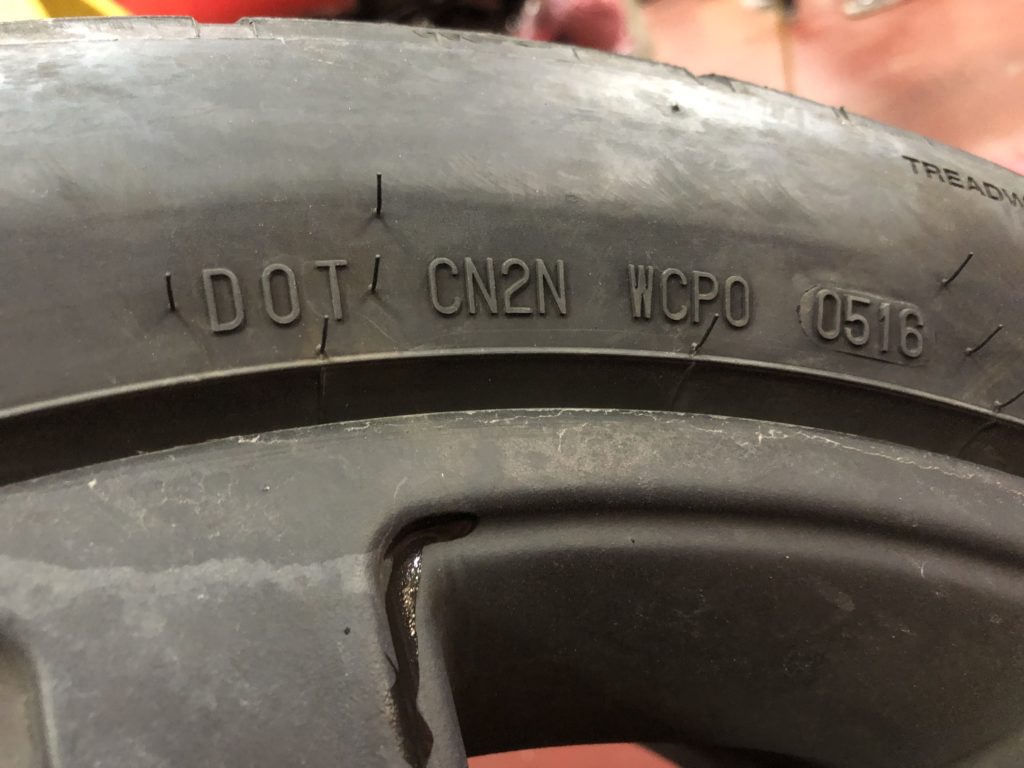

Older vehicles (produced in 1995 or before) get an actual tailpipe emissions test with a gas analyzer to measure vehicle emissions. Any car produced in 1996 or later gets an OBD2 test. The technician will plug into the vehicle’s computer and check to make sure emissions systems are ready. In Utah, you can have one emissions monitor fail but still pass the inspection. If two monitors are not ready, the vehicle will not pass.

Get a Utah emissions inspection at Matson Point S!

Time for an emissions check? Our technicians will make sure your car passes its emissions check and if it doesn’t, recommend and complete the repairs needed to get it passing. Give us a call and schedule an appointment at our Riverton, Utah shop today!